So simple but yet so few succeed....especially in a Maintenance environment! 5S has many applications in a maintenance, yet it seems a struggle for many, having tried and failed or not sustaining what has been achieved but also improvements into the future.

So why is it many companies struggle to make a start with 5S in maintenance and often if they do, struggle to sustain their efforts?

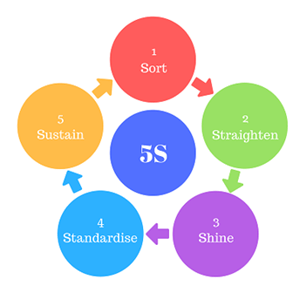

The crux I would suggest relates to both making a start and making it sustainable, is really about beginnings...what is needed to setup for success to put in place and have in place for sustained improvements…it is often this preparation that is forgotten or insufficient. While it’s the 5th S that is about Sustain, its often missed what is needed upfront and at the beginning and as result, 5S ironically never ever gets to the 5th S.

So what is needed for the best beginning and for sustainable 5S in maintenance?

5S in maintenance needs to be considered as a management of change and often in the maintenance space it can be quite a change. SIRF teaches the elements of managing change and we spend a whole day on this as part of our Leadership program.

However, some essentials for the best start and ongoing success would be:

The need – there very much has to be an accepted need and sense of urgency with not only leadership, but also within the team to kick 5S off. It has to have both the leadership and team behind it or will likely falter in the longer term or never take off. This is especially important in the maintenance space that given the constantly varying priorities maintenance face and the need for 5S often coming externally from the team.

Team approach – this can’t be down to one person, there needs to be a team guiding its success, key stake holders, those keen for its success to not only guide but coordinate and help with communication. This is absolutely key to initial success but also sustainability particularly in maintenance where teams can be quite diverse from a team of individuals pulling in different directions to a tight nit group that you want behind the initiative for success.

Having a vision – there needs to be a vision, this not only helps to engage the maintenance team to be part of the change involved, but also is helpful in sustaining the efforts for the longer term. The vision requires specific initiatives especially ones to deliver short terms wins initially to spur on success.

SIRF’s library is quite extensive and has some very good learnings on implementation of 5S in maintenance. Graham Regan National Reliability leader at News Corp recently presented at our National forum and if you search the library using the Tag Search “5S” via the link below https://www.sirfrt.com.au/resource-library

You will find Graham’s presentation sharing how 5S in maintenance has been sustained at News over the last 9 years! with some insights gained including,

- Work on culture and leadership first – be prepared for 5S

- Start small

- Work on culture before trying to introduce something

- Reflecting on whether you are in the right spot to start – not just the physical process, it’s the culture and environment.

Additionally, we have had in recent times a successful application of 5S with the Asahi Maintenance Team; see previous SIRF blog: Asahi Maintenance Team Applies 5s, where we have Shane Cameron (Maintenance Planner), who was the project manager for this upgrade saying that while there was initial resistance it was the team seeing the benefits that had them on board. The importance of support from leadership and being supported Top down, also how key it was for the Team to have both input and ownership for the results.

As will read in the blog it wasn’t all plain sailing, and 5S in maintenance is still not a walk in the park! If wanting to come learn more and share with others on this interesting topic, come join the SIRF Maintenance Workshop 'Organisation and 5S Common Interest Work Group' at Nufarm Laverton on 28th November in VIC.

Maintenance Workshop Organisation and 5S

There is no charge for SIRF members to attend and this workshop is really about beginnings. and what is needed to setup for success, to put in place and have in place for sustained improvements.

Nufarm have enthusiastically been heading down the path of 5s in a maintenance workshop, they are kindly hosting this workshop and will share on their experience and insights. This will be an opportunity to hear their journey of 5S in a maintenance workshop while also creating an opportunity to share and learn from others attending. There are only very limited spots available for this workshop so book on early rather than missing out!

Alain Le Bon